WASTEWATER VOC STEAM STRIPPER

Project Overview

Project intended to provide additional treatment and VOC removal to Owner's aqueous waste stream that is injected into an existing deep well system. Detailed design, construction and commissioning phase activities through installation and start-up. The project was completed on a phased and accelerated schedule to meet environmental objectives and deadlines established by Owner's management. The project was also completed below the project budget.

Services Provided

Architectural, Civil, Structural, Mechanical, Electrical, I&C, Chem. Process, Construction Management

UNDERGROUND FUEL OIL PIPING REPLACEMENT

Project Overview

New environmental regulations were requiring buried fuel oil piping to be taken out of service and replaced with above ground piping. The project was done in phases in order to limit the time the facility was without fuel oil. Century A&E performed field verification of existing drawings, modification to existing piping and instrument diagrams (P&IDs), pump sizing and specification, piping drawings, hanger details, structural modifications, pipe bridge design and power and instrument wiring diagrams.

Services Provided

Piping Design, Structural Engineering and Instrumentation, Power & Controls

Replacement of Four Juice Storage Tanks

Project Overview

Project involved the demolition and removal of existing Juice Storage Tanks and the installation of new storage tanks and new juice transfer pump with a VFD. The new storage tanks were larger in order to provide more storage capability. The operation of the storage tanks was upgraded to integrate with the existing operation which included installing a PLC and other controls. With the increased capacity the clean-in-place operation was increased for the tanks and larger diameter piping. Modifications to the truck unloading operations to service their new storage tanks were also included.

Century A&E performed the sizing and specification of the replacement tanks, pump, instrumentation and controls. Prepared bid documents for mechanical and electrical contractor installation. Coordinated the installation with maintenance and manufacturing. Validated the installation, following the client’s standard operation procedures.

Services Provided

Chemical Process, Piping Design, Instrumentation & Controls, Electrical, Structural Engineering, Construction Management, and Qualification Services

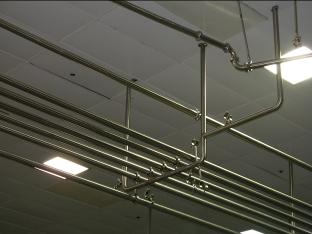

Clean-in-Place (CIP) Upgrade to Allergen Process Equipment

Project Overview

This project was designed to upgrade the glass processing equipment CIP loop to meet requirements for cleaning the piping and equipment involved in processing potential allergens. The CIP operation was upgraded to integrate with the existing CIP equipment PLCs. It included addition of new instrumentation and controls in order to document and validate the cleaning of the process loop. A functional description was created to incorporate the new controls into the existing PLC.

Century A&E performed the sizing and specification of the various equipment, pumps, valves, instrumentation and controls. Piping plan and elevation drawings along with wiring diagrams and one-line drawings were created along with bid documents for mechanical, electrical and integrator contractors.

Services Provided

Chemical Process, Piping Design, Instrumentation & Controls, Electrical, Structural Engineering